Exportation of Proteoglycan to South Korea

Currently, small booming of proteoglycans is happened in South Korea. And we are receiving many contacts for salmon nasal cartilage extract include proteoglycan.

In Japan, there are three types of proteoglycan products (raw materials) as follows.

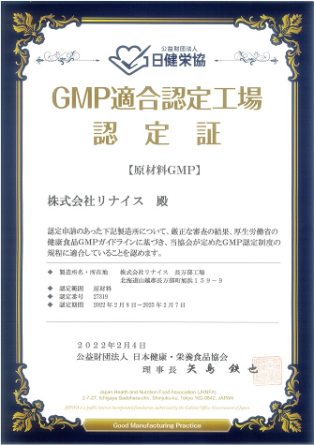

1. A product manufactured from the extraction process to powdering process in GMP certified factory, such as Linise.

2. A product partially manufactured in GMP certified factory.

For example, this product is manufactured only the powdering process in GMP certified factory as final processor and be manufactured the most important process (the extraction process and the purify process) in Non-GMP certified factory.

3. Products manufactured in Non-GMP certified factory, low level factory.

which we handle, raw materials that are not manufactured at GMP factories, and raw materials that are only used at GMP factories in the final powdering (doubling) process.

In several Asian countries such as South Korea and China, dietary supplements must be manufactured at GMP factories, and it’s the best that the raw materials used for dietary supplements are manufactured in GMP factories or any facilities have the almost same level certifications (ISO 22000, etc.).

In our experience, when exporting raw materials, it is necessary to manufacture at GMP factories in Thailand and Malaysia. In addition, even if it is developed as an individually certified functional food in Korea, it is required to be manufactured at GMP factories.

In addition, in order to claim the undenatured proteoglycans and type II collagen derived from salmon nasal cartilage, standardization based on the analysis of high-level methods is required. In the case of undenatured proteoglycans, the determination analysis limited to a certain molecular weight (about 420kDa or 900-1500kDa) by HPLC is required, rather than analytical methods such as carbazole sulfate method or barium sulfate gravimetric method.

Also, the undenatured type II (&XI) collagen requires determination analysis while confirming the polymer state (about 100kDa x 3 lines), as in the electrophoresis method.

>> New information: about New Specification

As we said before sentence, the manufacturer that we selling as a primary distributor (agent), Linise is manufacturing from the extraction process to powdering process at their own GMP factory certificated from Japan Health and Nutrition Food Association. In addition, this factory has also obtained Kosher certification and Halal certification.

And we are currently conducting 90-day repeated toxicity studies and next human clinical trials and be developing them based on overseas strategies.

Due to this kind of manufacturing management and research and development, it is not suitable to compete on only costs without qualities.

Exportation to South Korea

When exporting raw materials to Korea, the 700g-1kg samples will be extracted at the time of customs clearance as a keep samples. High-priced raw materials like our salmon nasal cartilage extract are no exception.

Please give attention to this point on the business.

In addition, quarantines in several companies are starting to request any analysis data of radioactive substances, because of the problem of the discharge of treated water from the Fukushima Nuclear Power Plant into the ocean.

Regarding the detail, please ask us the circumstance and our correspondence.

Attention:

Linise never sell their products directly. Only primary distributors can sell their products. And we are the biggest primary distibutor developing their researches with Liniess. Because Dr. Kuriyama of A2Pro is one of scientific advisor of Liniese.

Factory inspection and photography

We have received many requests for inspections and photographs of Linese’s factories.

In principle, we are requesting the purchasing of SCP Complex-LS for 30 kgs (Proteoglycan-LS for 10 kgs) or more. And we are arranging it after the payment.